Make sure to use all of the proper safety equipment.

-Try to find shirt that is thick, %100 cotton.

-Your welding gloves should be insulated and fire resistant.

-Try to use a helmet with a lens that automatically darkens during the welding process. The lens should be rated at 10-13 shade.

-Make sure that your pants do not have cuffs that can catch flaming material.

-Keep a fire extinguisher easily accessible in case of nay stray sparks.

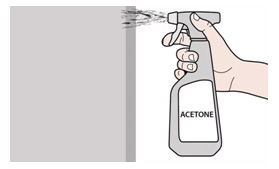

Clean tha aluminum.

-Spray the joints with acetone. Rinse the work piece in water, and then allow it to dry throughtly. Scrub the aluminum with a stiff brush with stainless steel bristles to finish the cleaning process.

-The welder itself will clean the metal as welds, but this is often not sufficient to remove all contaminants.

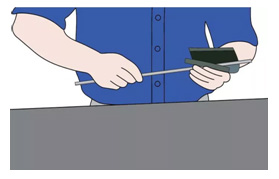

Clean the filler rod.

A dirty filler rod can contaminate the weld just as easily as a idrty work piece. Use an abrasive cleaning pad to ensure that the rod is contaminant free.

Aluminum is much easier to weld when the work is already much hotter than room temperature. When welding thick pieces of aluminum, welding without preheating can lead to a very weak, shallow bond.

-You can heat the work piece by putting it directly in an oven or you can use a gas torch to apply heat sink that the work is clamped to. This will distribute the heat throughout the work piece.

-Aim for temperature of about 350°F (176°C)